Ol-Class Replenishment Oiler

An Ol-class replenishment oiler that was rebuilt by Iranian naval shipbuilding for the navy of Islamic republic of Iran army in 2015. It is designed to conduct the traditional naval tasks as well as maritime security operations. ARMANIK was responsible for the engineering, supply, installation and commissioning of the whole HVAC systems' and cold storage compartment as follows :

AMD accommodation

AFT accommodation

Student Dormitory

MCR and switchgear spaces

Cold storage compartment

Challenges

Technical challenges (among other contractors)

Shock, vibration and EMC requirements

Vulnerability requirements for certain systems

Space constraints for the routing & handling and transporting of electrical panel, compressors ,fans ,ducts and pipes

Incompatibility of new equipment and control system with some existing equipment

Time schedule limit

Lack of data and shipbuilding calculations

Different source of electrical power supply

Scope of work

ARMANIK’s scope of work for the above project comprised:

Pre-contract

Co-writing technical specifications and implementing and calculating of load the HVAC system within the vessel design.

Post-contract

Complete design and engineering of the HVAC systems, followed by delivery, installation, commissioning, FAT, HAT, SAT and ILS activities.

Vessel was reconstructed by iranian Naval Shipbuilding in the persian gulf .

Scope of supply

Among several smaller items of equipment, the following main equipment was supplied.

AMD Section

1x Air-treatment unit with control panel

1 x Rack plant with control panel and compressor redundant operations

2 x Sea water cooled condensers

System monitoring from upstream

AFT Section

2x Air-treatment unit with control panel

1 x Rack plant with control panel and compressors' redundant operations

3x Sea water cooled condensers

System monitoring from upstream

Student Dormitory

2x Air-treatment unit with control panel

1 x Rack plant with control panel and compressors' redundant operations

2 x Sea water cooled condensers

All ducts and duct work

System monitoring from upstream

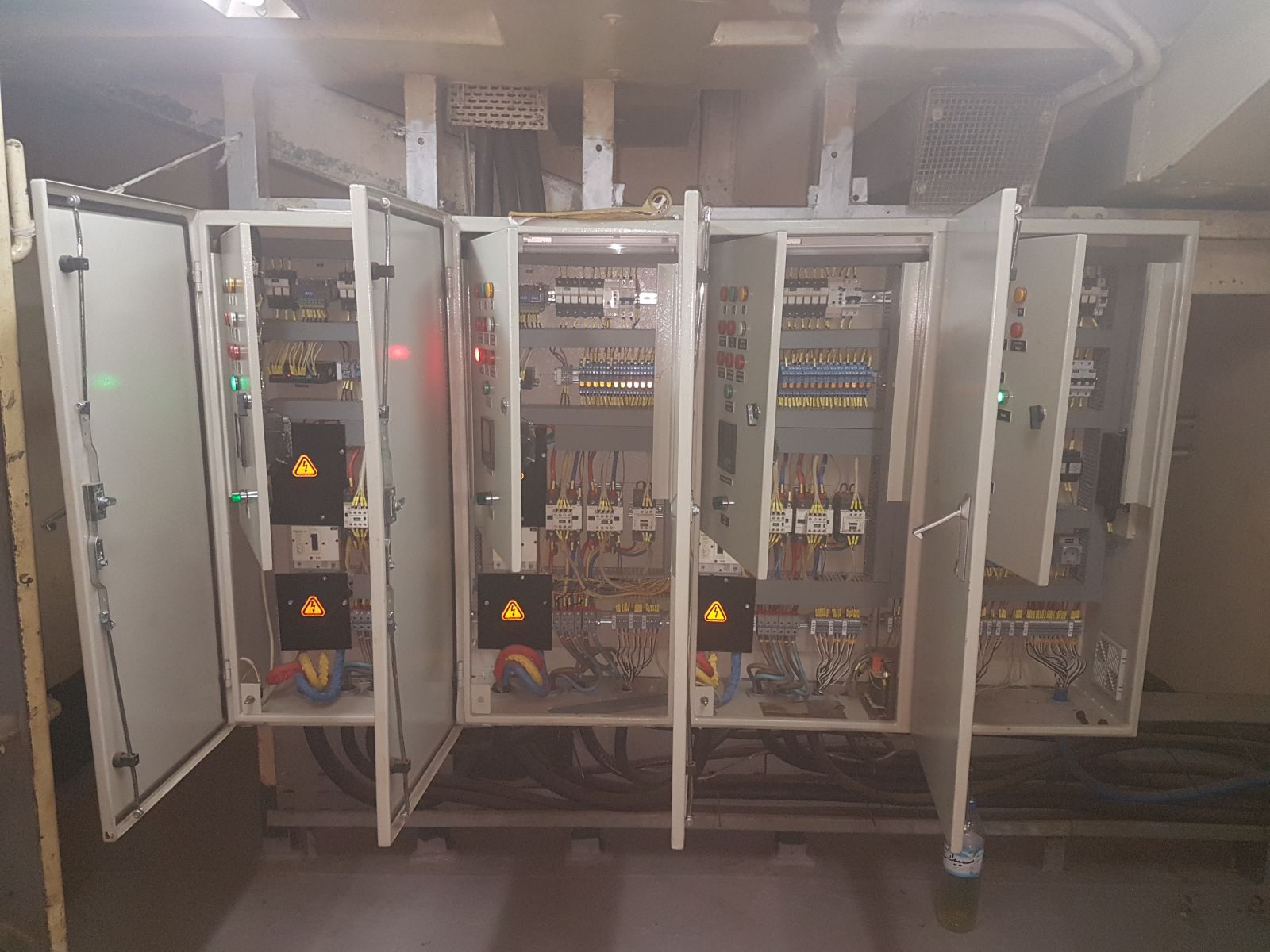

MCR and Switchgear spaces

3x Air-treatment unit with control panel

1 x Chilled water plant with control panel

2 x Chilled water booster pump

Cold storage compartment

1 x Provision refrigerant unit with control panel

3 x Evaporator

.jpg)

.jpg)