Plastic Industrial

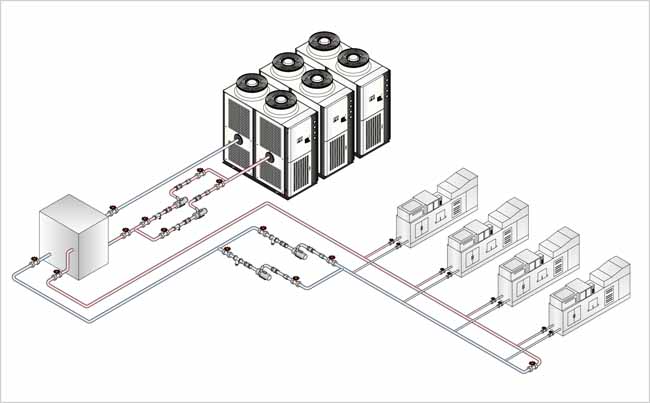

All processes of converting polymers into plastic parts require accurate and efficient cooling. Regarding to benefiting for the efficiency ,production speed, uptime and cost saving , the plastic provider use closed-loop cooling at their injection molding process including blow mold ,thermoforming and extrusion . Our innovative chillers enable plastics producers to significantly reduce their manufacturing costs by halving power consumption for cooling

All processes of converting polymers into plastic parts require accurate and efficient cooling. Regarding to benefiting for the efficiency ,production speed, uptime and cost saving , the plastic provider use closed-loop cooling at their injection molding process including blow mold ,thermoforming and extrusion . Our innovative chillers enable plastics producers to significantly reduce their manufacturing costs by halving power consumption for cooling

1- Energy Cost Reduction. The closed-loop system can help by reducing energy costs associated with plastics process cooling compared to air cooled central chilling systems.

2- Water and Environment Conservation. Unlike cooling tower systems, process water doesn’t evaporate in the closed-loop system, delivering water savings of up to 97 percent. Plus, the water is never exposed to outside elements, providing a big boost to sustainability efforts.

3- Repeatability. Providing control and record ability of water temperature, flow and pressure at each machine, and the ability to preheat, fill and drain molds automatically, Armanik process cooling technology makes it easy for you to get reliable, predictable results every time.

Related Process :

Related Process :

1. PET Preforms & Bottles

2.Rigid Packaging

3.Automotive components

4.Technical parts

5.Medical solutions

6.Thermoforming & Technical Sheets

7.Flexible Film

8.Pipes, Profiles, Cables

9.Fibres & Strapping

10.Recycling & Compounds